Liquid Dosingsystem LDS

High-precision dosing of liquids

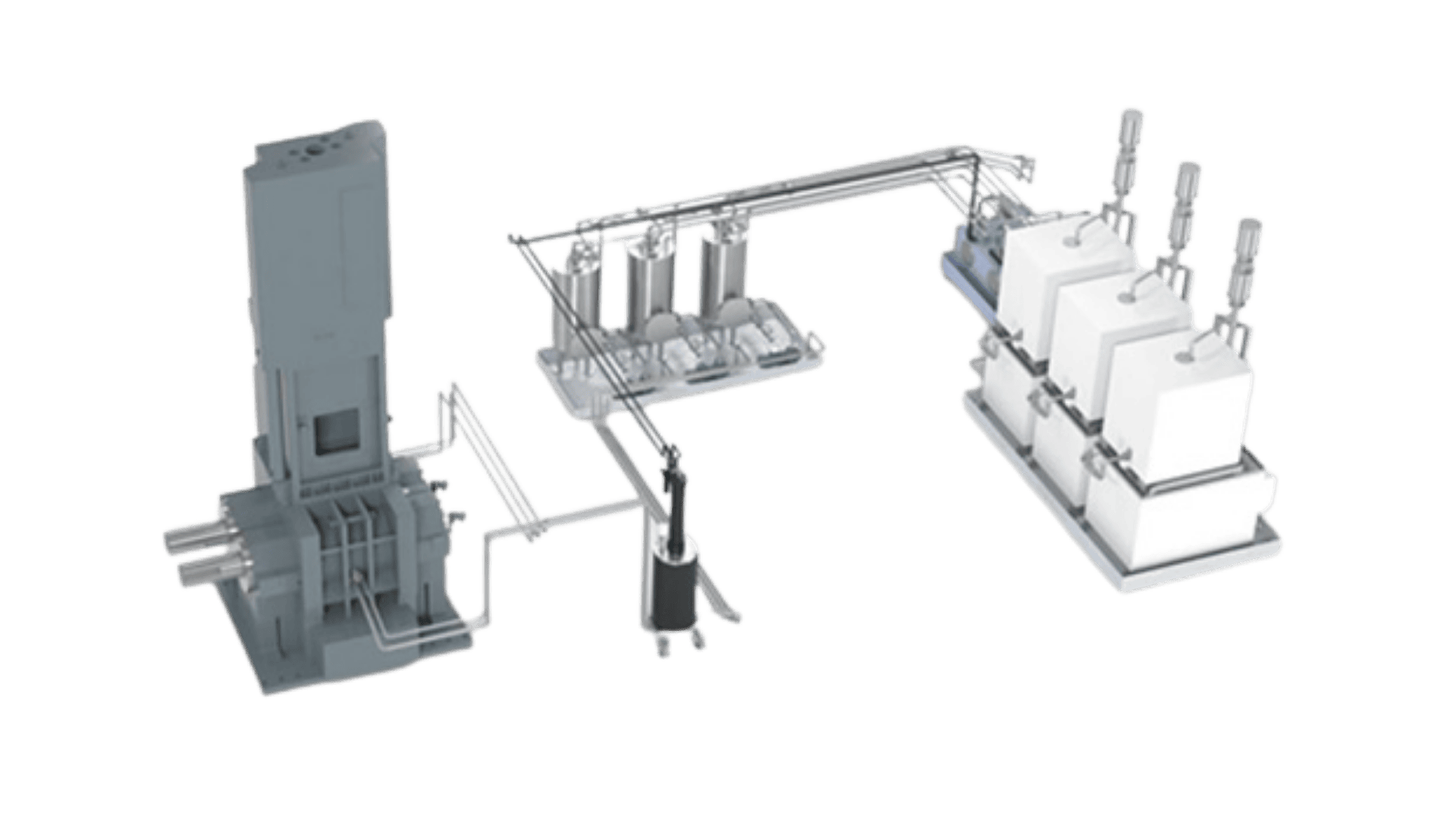

The Liquid Dosing System (LDS) is a robust, modularly expandable dosing system. It enables accurate volumetric batch dosing of up to 36 low- to high-viscosity liquids with high flow rates in a fully enclosed transfer system all the way to the mixer line. Through individual temperature conditioning of each medium, the system ensures maximum reliability and throughput capacity without any risk of contamination – while maintaining excellent dosing and injection accuracy. The LDS replaces conventional liquid dosing equipment and eliminates the typical over‑dosing and associated cycle time losses, thereby reducing raw‑material costs and minimizing waste

Highly flexible liquid dosing system tailored to your application

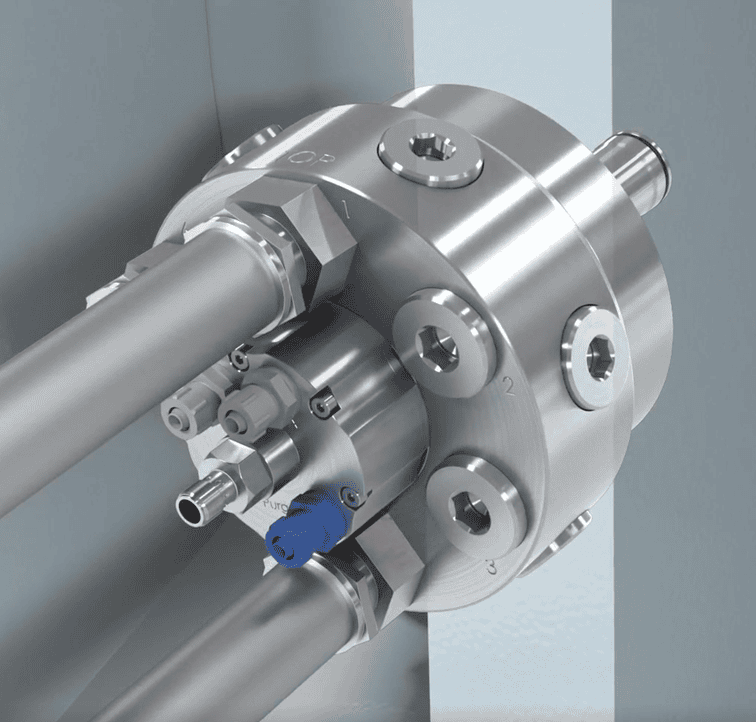

In addition to the modular components for storage, temperature conditioning, and media supply, the hydraulically driven dosing cylinder (LDC) and the manufacturer-independent 6-nozzle mixer injection valve are the core components of the modular system. The dosing cylinder allows sequential injection of up to four liquids, while the injection valve provides a universal interface for injecting up to six different liquids into various mixer types. This facilitates flexible use or retrofitting of the LDS station to multiple mixer lines. For the operator, this results in the following advantages:

- Closed, insulated system

- Prevention of cross-contamination

- Precise dosing of high-viscosity media

- High flow rates independent of viscosity

- Savings in energy consumption and raw material usage

- Modular and scalable system design

Perfect dosage. Drop by drop.

High dosing accuracy and speed

These features lead to lower raw‑material costs, as materials are utilized precisely and efficiently. At the same time, material losses are significantly reduced, increasing overall process profitability. In addition, this ensures higher batch availability and smoother production workflows.

Flexibility

Injection parameters can be configured variably — slow, fast, or sequential —depending on process requirements. Furthermore, multiple liquids can be processed within a single batch, enhancing the adaptability of the entire production process.

High throughput performance

High flow rates are achieved while maintaining consistent performance regardless of the viscosity of the media being processed.

Safety

A closed, insulated system prevents the formation of aerosols in the ambient air and simultaneously contributes to reduced energy consumption. In addition, the air purging function of the injection valve prevents cross-contamination.

Efficiency

A fast‑acting valve shut‑off minimizes material waste by preventing dripping, leakage, and over‑dosing

Ease of servicing

Simple installation and easy cleaning and maintenance mean low operational effort.

Engine

The drive is powered by a hydraulic power pack with an operating pressure of min 120 bar at 50l/min .

Operating conditions

The unit is designed to operate within an ambient temperature range of +5 °C to +40 °C, while processing media temperatures from +20 °C to +90 °C.

Closed system – maximum process accuracy!

The Liquid Dosing System (LDS) features media-specific subsystems and modules, such as dedicated components for liquid storage. Enclosed single and double container stations are available for pre-heating the IBCs, along with open container stations and intermediate tanks for liquids supplied from the oil storage area. The ring line in the container station to the dosing cylinder(s) is heat-traced and operates independently from the mixer line. The dosing cylinders themselves are designed according to product requirements and are available in various capacities (30/60/90 l). The hydraulic unit (Hydraulic Power Pack), which comes in three sizes, supports operation of up to eight dosing cylinders. The injection valve is universal and therefore suitable for any type of mixer. Up to six injection valves per mixer can be installed, enabling the introduction of up to six different liquids into the mixing batch.

Precise and reliable injection of liquids

Special highlights

Dosing capacity

Dosing time

Injection time

Direct dosing of process oils and plasticizers

The LDS is primarily used for storage, conditioning, volumetric dosing, transfer, and injection of liquid media. Typical media include oils, silanes, antioxidants, liquid rubbers, resins, solvents, and accelerators used in mixers in the rubber and tire industry.

Key facts at a glance

Precise injection and dosing

When a campaign change or recipe adjustment is required, the dosing process must be adapted quickly and reliably. This is exactly where our LDS liquid dosing system comes in. For many years, it has impressed with its high precision, short response times, and maximum process reliability, and is therefore successfully used in numerous plants in the tire and rubber industry. The LDS is an automatic, closed batch-based dosing system designed for the precise metering of process oils and plasticizers. It was specially developed for use in powder mixers in the rubber and plastics industry and enables clean, reproducible, and efficient integration into existing production processes.

Sizes

Dosing system for up to 36 liquids

Area of application

The system is suitable for silanes, resins, process oils such as TDAE, RAE, MES, naphthenic, rapeseed or recycled oils, solvents and highly viscous liquid rubbers in the manufacture of rubber compounds.

Pressure range

40 bar

Temperature range

Ambient +5 °C / + 40 °C, media +20 °C / +90 °C

Engine

Ambient +5 °C / + 40 °C, media +20 °C / +90 °C

Viscosities

Up to 7000 mPas

Materials

Media-specific

Advantages for the industry

Rubber & Tire

As recognized process experts, we know every step of the rubber and tire industry in detail. Our well-thought-out solutions provide you with measurable advantages across the entire value chain, including the recycling of end-of-life tires.

Go to rubber & tire industryNeed more details? Our contact person will be happy to assist you

Our Customer Services for You at a Glance

Show all Customer ServicesExplore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH